In a global where automation maintains to reshape entire industries, china has once more taken a formidable leap into the future. The brand new headline-making innovation? A fully computerized vehicle assembly line that produces a vehicle every 45 seconds — with out a unmarried human employee on the floor.

This cutting-edge improvement isn’t just about velocity — it marks a progressive turning point in how the automobile industry operates. Here’s a more in-depth take a look at how china is transforming manufacturing, and why the world is looking carefully.

The upward push of the unmanned manufacturing facility

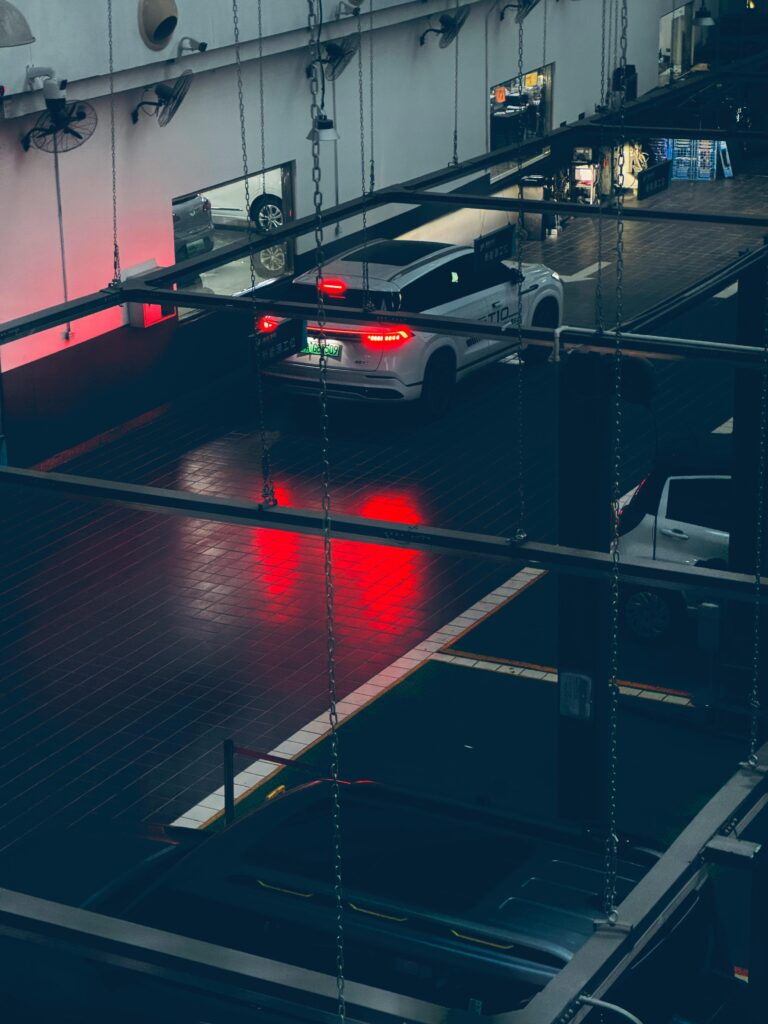

China’s automotive enterprise has lengthy been recognized for its scale, however this new facility takes efficiency to a wholly new level. Operated by considered one of china’s main automakers — often alleged to be a joint project among principal manufacturers and ai tech firms — this plant uses a aggregate of robotics, ai, device imaginative and prescient, and real-time information analytics to construct vehicles with 0 human intervention on the primary line.

From welding and painting to installing engines and acting high-quality control tests, each step is executed by way of wise robotic structures working in perfect harmony.

How does it paintings?

- Precision robotics

On the heart of the gadget is a fleet of superior commercial robots. Those aren’t ordinary factory fingers — they’re equipped with ai-based totally adaptive control structures. Meaning they are able to regulate at the fly, understand exceptional automobile models, and locate variations in parts or substances to make certain precise meeting on every occasion. - Ai-pushed logistics

The flow of components is treated through autonomous mobile robots (amrs) that ferry parts from one station to another with pinpoint timing. An ai manage middle oversees the entire environment, dynamically optimizing the supply chain and manufacturing series to keep away from delays or bottlenecks.

Three. Clever high-quality manage

In contrast to conventional nice warranty strategies that rely on manual inspection, this system makes use of high-decision cameras, lidar, and thermal sensors to inspect every car in real time. Ai algorithms right away flag potential problems and make instantaneous corrections — ensuring near-perfect pleasant at scale.

Four. Real-time monitoring

All structures are interconnected via the industrial net of factors (iiot), allowing engineers (off-site) to monitor, replace, and troubleshoot the road remotely. Dashboards track manufacturing statistics right down to the millisecond, presenting insights and predictive preservation alerts before troubles rise up.

Why it’s a huge deal

⚡ unequalled velocity and performance

A car each 45 seconds isn’t simply fast — it’s enterprise-disrupting. Compared to traditional meeting lines that might take numerous mins per car, this pace can reduce production fees dramatically and meet growing global demand with less overhead.

👷 0 on-web site labor

The absence of human people on the floor way decrease dangers of accidents, no exertions shortages, and decreased operational fees. Whilst people nevertheless play a position in supervision, programming, and renovation, the physical manufacturing is totally automatic.

🌱 sustainable manufacturing

With optimized processes and minimum waste, the line is also drastically extra energy-green. Robots function with consistency, decreasing fabric overuse, and smart structures adjust electricity intake based on production quantity.

Global implications

China’s innovation isn’t always only a countrywide milestone — it is a sign to automakers around the globe. As automation turns into more reachable and inexpensive, this model may want to redefine how motors are manufactured international.

International locations closely reliant on conventional hard work-based totally meeting lines can also want to reconsider their strategies to live competitive. Alternatively, this shift may spark moral debates and concerns about process displacement and the role of human beings in an increasingly more computerized economy.

What’s next?

At the same time as fully automated vehicle factories are still rare, china’s achievement story might also boost up international adoption. The following frontier? Customizable manufacturing, in which ai not most effective builds the vehicles however helps design them on-demand, tailor-made to individual customer possibilities.

We’re getting into an era in which production is now not bound through human obstacles. Whether or not it’s evs, hybrids, or independent automobiles, the destiny of manufacturing may be faster, smarter, and completely robot.

Final mind

A car each forty five seconds — with no people on the road — sounds like a concept from a sci-fi novel. However in china, it is already a truth. As other countries race to catch up, one issue is clear: the age of smart, automated manufacturing is no longer within the future. It is right here, now — and it is changing the whole lot.